Reviving classics: Sinterit SLS 3D printing drives automotive innovation

1. Smart solutions for custom car parts

3. How OctoClassic used Sinterit SLS 3D printing to solve real problems?

4. Why Sinterit SLS 3D printing matters?

5. Conclusion

Smart solutions for custom car parts

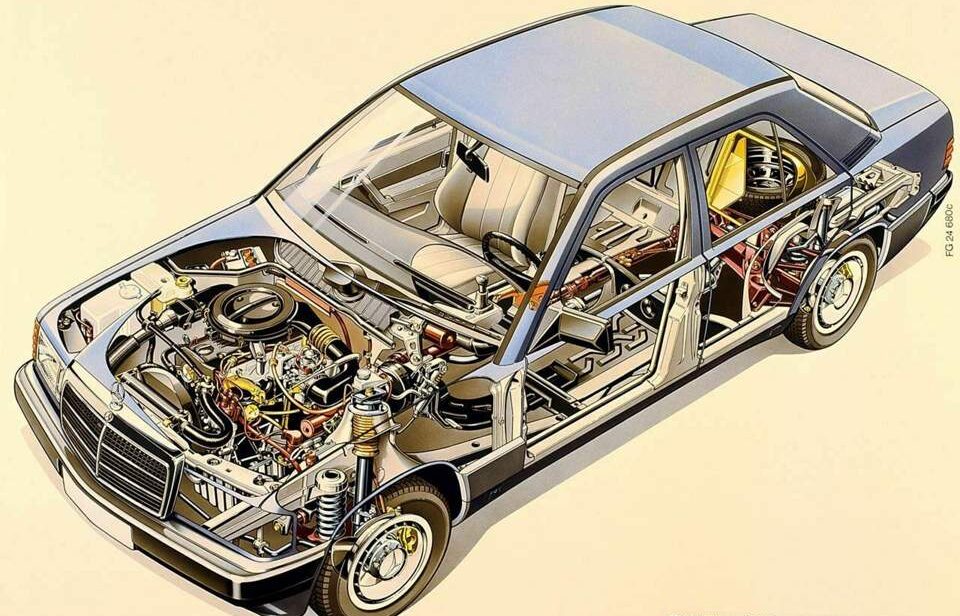

We recently completed an innovative project in collaboration with Sinterit, a leader in SLS 3D printing technology, and Broler Company, a specialist in precision manufacturing. The aim of this joint effort was to find effective methods for producing high-quality car parts that are no longer available on the market or require improved durability.

Our case study focused on three main challenges often encountered in classic car restoration and custom vehicle projects:

- Redesigning parts to improve reliability – Original components often suffer from outdated designs or weaknesses that cause premature wear. By rethinking and optimizing these designs using CAD tools and additive manufacturing techniques, we created stronger and more functional replacements.

- Manufacturing unavailable parts – Many car parts, especially for classic models, are no longer produced. Traditional manufacturing methods like casting or machining can be too costly or slow for small batches. Thanks to SLS printing, we were able to produce complex, precise parts quickly and cost-effectively.

- Using advanced, purpose-matched powder materials – Material choice is critical for part performance. We used SLS powders selected specifically to meet the mechanical and thermal requirements of each part, ensuring both strength and resistance under real-world conditions.

What is Sinterit?

Founded in 2014 in Poland, Sinterit is a technology company with a mission to make industrial-grade SLS 3D printing accessible to professionals across various industries. The founders, Konrad Głowacki, Michał Grzymała-Moszczyński, and Paweł Szczurek, introduced the world’s first affordable desktop SLS printer — the Sinterit Lisa — in 2015. This innovation created a new category in the 3D printing market, giving engineers, designers, and small businesses access to a technology once reserved for corporations with six-figure budgets.

Sinterit’s product line has since grown to include several compact and high-performance SLS printers. These machines enable in-house production of complex, durable parts without the cost or delays associated with traditional manufacturing methods.

But Sinterit is more than just a hardware company. Its values — teamwork, creativity, and big-picture thinking — shape everything they do. With nearly 100 employees and a global reach, Sinterit continues to push boundaries in additive manufacturing.

How OctoClassic used Sinterit SLS 3D printing to solve real problems?

At OctoClassic, we specialize in restoring classic vehicles — but as every restorer knows, sourcing original parts is often impossible. That’s where Sinterit SLS 3D printing became a game-changer for us.

- Redesigning Classic Parts for Modern Reliability: Many vintage components were never built for longevity. We used CAD modeling and SLS printing to redesign these parts while retaining their original form. With optimized geometry and stronger material properties, our updated parts are more durable and functionally superior.

- Replacing the Unavailable: Some parts we needed simply no longer exist in the market. Rather than compromise or search endlessly, we recreated them using Sinterit’s SLS printers — accurately, affordably, and on demand. This gives us full control over quality and delivery timelines.

- Tailoring Materials to Automotive Demands: Not all 3D printing powders are created equal. Fortunately, Sinterit offers a range of technical materials optimized for specific mechanical, thermal, or chemical requirements. For every part we created, we could choose a material that exactly matched our performance needs.

Why Sinterit SLS 3D printing matters?

Our collaboration with Sinterit has enabled us to elevate our restoration services. It’s no longer just about restoring the past — it’s about enhancing it with the tools of the future. Sinterit SLS 3D printing gives us the ability to preserve authenticity while ensuring modern-day reliability.

Moreover, additive manufacturing reduces waste, shortens lead times, and eliminates the need for large inventories. It aligns perfectly with our goal of delivering sustainable, high-performance solutions in the automotive restoration world.

Conclusion

Thanks to our collaboration with Sinterit, OctoClassic can now quickly produce precise, durable parts for classic vehicles. SLS 3D printing gives us full control over quality, fit, and performance.

For anyone working in automotive restoration or custom manufacturing, this technology is a practical and scalable solution. It’s helped us bridge the gap between vintage design and modern engineering.