About us

We Design spare parts for classic cars.

Founders meet and get the first spare part designed for R129.

Octoclassic was officially founded.

Octoclassic opens a manufacturing facility in Europe, expands to United Arab Emirate.

100,000 parts shipped to customers.

1,000th spare part designed in our catalogue.

Buying directly from the manufacturer….

…Means that we can offer the best possible price for our high quality products, without additional overhead for any middle-men companies.

We got all 50 shades of gray…

…and other colors too!

Our specialists will help you with matching the color of your spare parts in no time. If our color database does not contain your color code, just share your needs with us and we will make a custom color for you!

100% orders delivered to 100+ countries

From Dominican Republic to the Kingdom of Brunei – thousands of our parts each month reach their new owners in various countries. In distant locations, our parcels need more time for delivery, buy hey – you have looked for those NLA parts for months already. Relax, it is just few days’ delivery!

The “WOW” effect…

…you have, when you see the quality of our hand-finishing is our ultimate goal.

Most of our customers say, that they have never seen such brilliant quality from “standard 3D printers” before. Of course – we do not use, “standard 3D printers”, but high precision industrial powder-bed machines you won’t find in your friend’s garage…

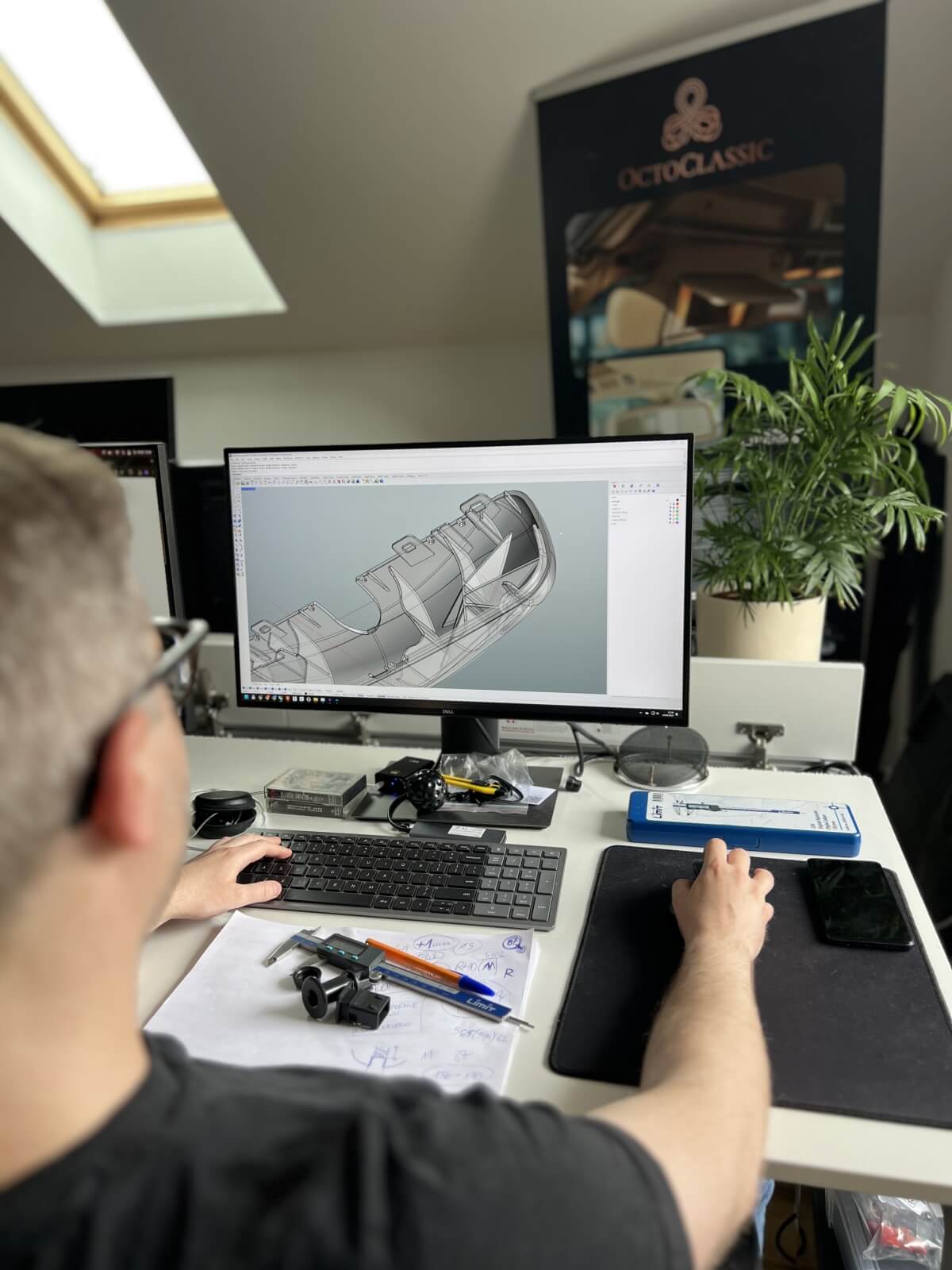

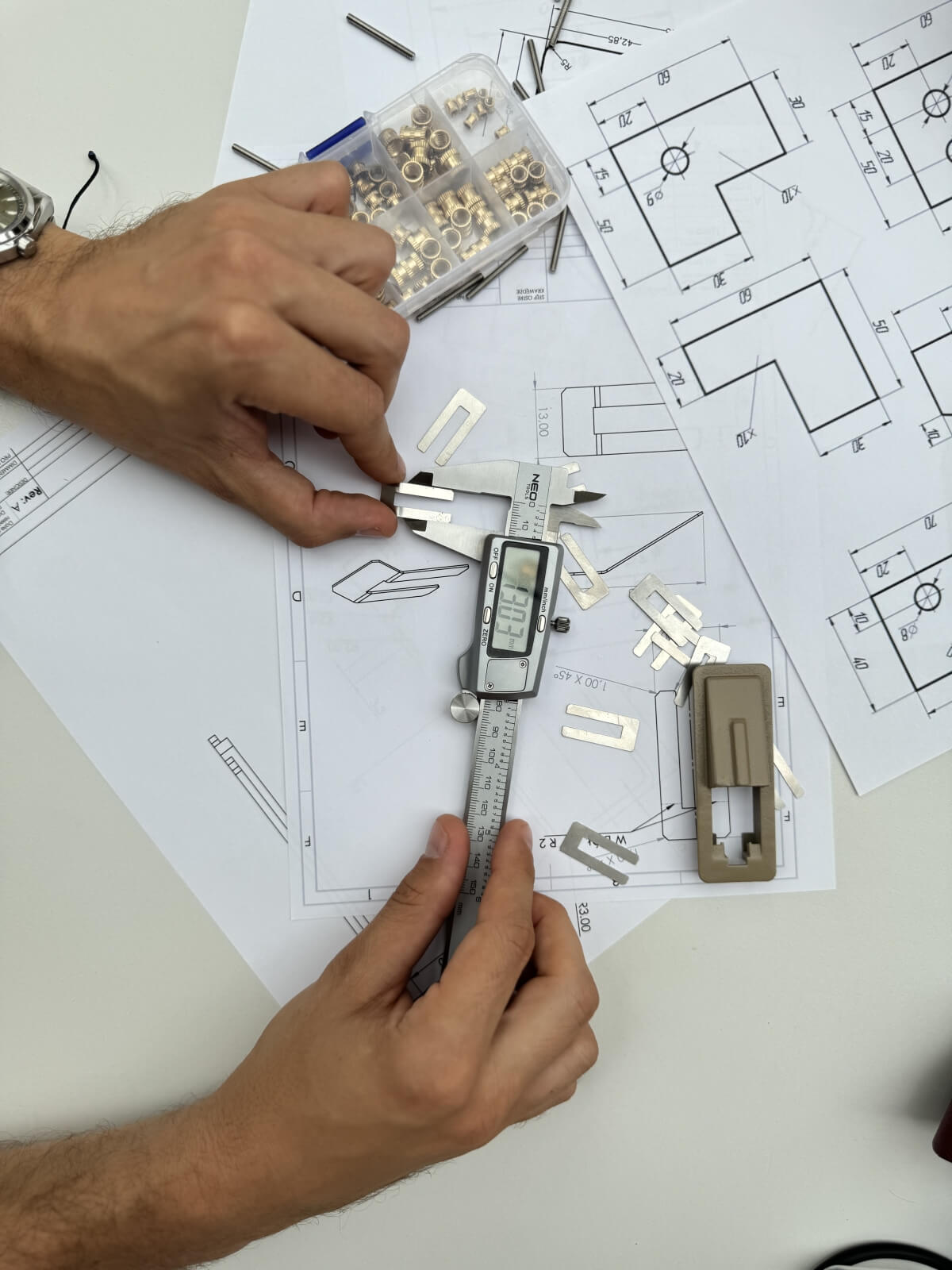

Redesigning “the perfect”...

…is in our DNA. It took OEM engineers years to design your car back in the day, and most of the time, the end parts were really great—until they broke. Nowadays, with modern technologies and materials, many of those spare parts receive slight improvements from our engineers, so even your grandson won’t need to worry about them again.

Our moms wanted us to become doctors…

…instead we have spent 10,000+ hours on recreating spare parts for our beloved classic cars, and built thousands of parts. We failed over and over before, that’s why we are now masters at what we do. Make sure you send us a challenging project.

Leather? Grain? High-gloss?

Let our designers help you with mathing your desired finishing. We can match the original type of finishing found in your car, but why not trying something custom you have always dreamed about?